Code EK000352

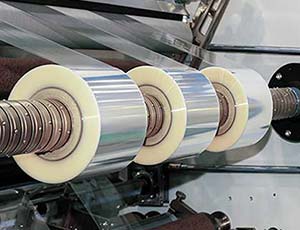

(2000) Dornier 6400 mm BOPET Film Extrusion Line

DORNIER

BOPP BOPET PACKAGING FILM EXTRUSION LINES

This 2 Layers co-extruded BOPET film extrusion line produced by DORNIER is used for the production of many BOPET film types for a wide variety of applications. DORNIER has developed high output lines for top quality film production.

This Second-hand 2 Layers DORNIER BOPET film machine allow a range up to 3.400 kg/h and a film width of 6.400 mm.

Technical Data | |||

|---|---|---|---|

REFERENCE MACHINE | BOPET/DORNIER | ||

MATERIALS | BOPET | ||

FILM WIDTH (MAX) | 6.400 mm | ||

NUMBER OF EXTRUDERS | 2 | ||

NET OUTPUT (MAX) | 3.400 Kg/h | ||

NUMBER OF LAYERS | 2 | ||

FILM ROLL MAX DIAMETER AT WINDER | 1.000 mm | ||

MAX MECHANICAL SPEED | 350 mt/min | ||

TYPE OF DIE | EDI (3 items) | ||

RUNNING LOAD | 1.910 kW | ||

FILM THICKNESS RANGE | from 12 µm to 60 µm | ||

STRETCHING RATIO TD | 4,1 | ||

STRETCHING RATIO MD | 3,40 - 3,10 | ||

BOPP/BOPET Extrusion Lines

BOPP (Biaxially oriented polypropylene) and BOPET (Biaxially oriented polyester) films are the most common supports used in the food packaging and printing. BOPET is more stable through printing and laminating processes than BOPP and is often preferred where high-quality graphics are required.

These plastic films are produced in tender-frame lines where the material (PP or PET) is melted through a flat extrusion die (T-die) and solidified onto a cooled roller. The material is then stretched in the machine direction in an MDO and then in the transverse direction in a TDO. Solid-phase orientation processes create very significant changes in film properties that can be quite valuable in packaging structures. These changes permit films that are lighter weight and thinner than standard blown or cast films to satisfy performance needs by generating significant increases in such properties as tensile strength, toughness, heat stability, tear initiation resistance, and barrier.

Both BOPP and PET films can be produced in a variety of thicknesses, making them suitable for different types of packaging applications. Various types of finishes, such as matte, glossy and metallic, are also achievable, allowing manufacturers to create packaging with different textures and visual effects. With the growing demand for individual packaging, BOPP and PET films are likely to remain popular choices for manufacturers looking to create high-quality custom packaging that protects their products and enhances their brand image.